Product

More Than 20 Professional Technicians Service for You

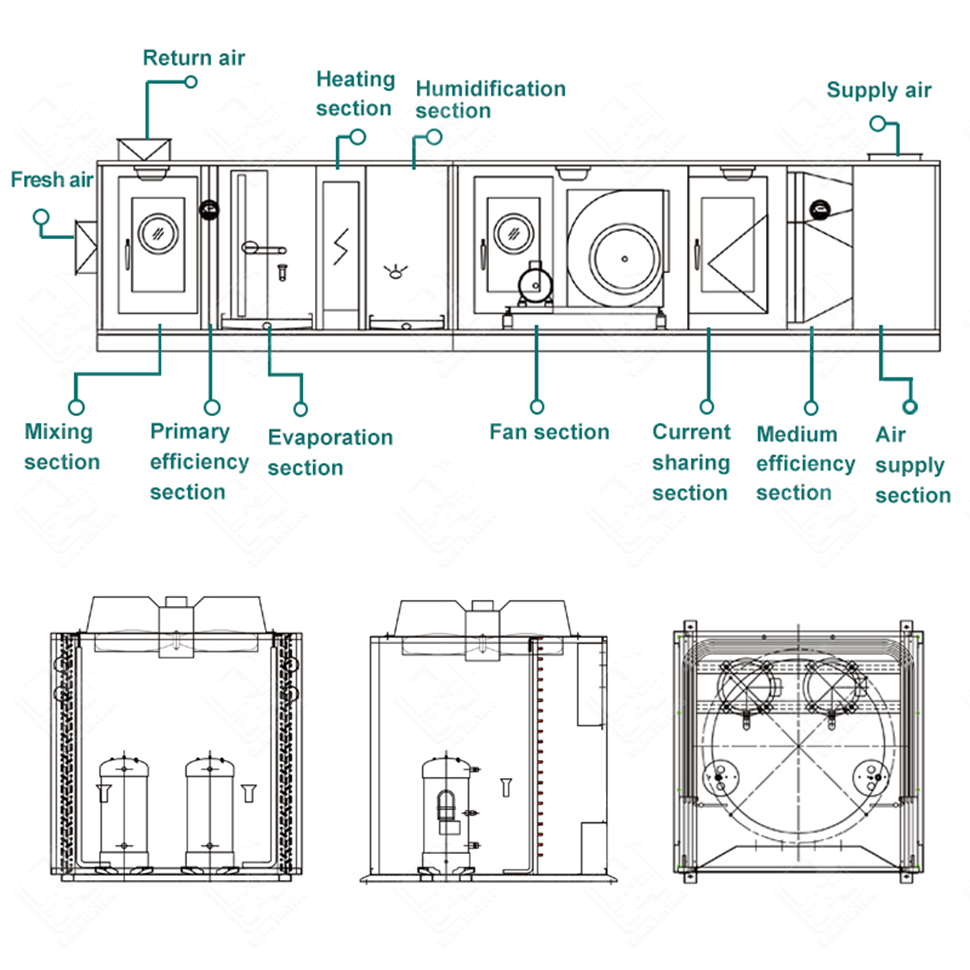

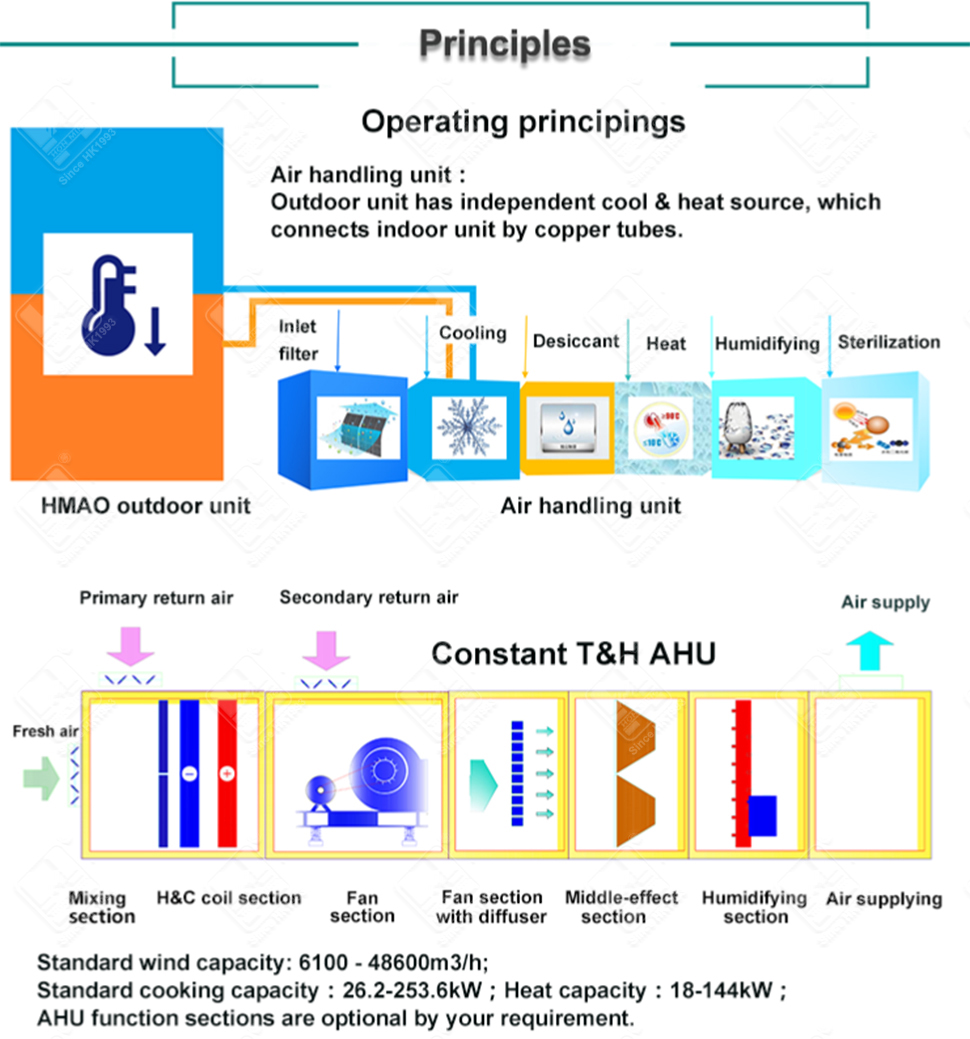

HMZK-D series DX AHU is composed of indoor combined air handling unit and outdoor chiller unit. Including: Cooling only type, heat pump type, purifying type, constant temperature and humidity type, fresh air type,etc.Indoor combined air handling unit can customized according special air handing needs of all walks of life.

Type: HMZK-D Series Direct Expansion Type

Air Flow: 6100-48600m³/h

Cooling Capacity: 20-300kw

Refrigerant: R22

HON MING HMZK-D series DX AHU adopts latest air source compression & condensation and air handling technology. Especially suitable for medical care and public health, bio-pharmaceutical,micro-electronics,automobile manufacturing, experimental research, food processing, schools, etc. The unit technical advantages: Built-in cold source,customized air handling, and control integration. The simplified system structure can realize flexible distributed applications, save engineering construction and operation costs, simple and high efficiency.

HMZK-D series DX AHU is composed of indoor combined air handling unit and outdoor chiller unit. Including: Cooling only type, heat pump type, purifying type, constant temperature and humidity type, fresh air type,etc.Indoor combined air handling unit can customized according special air handing needs of all walks of life.

Especially suitable for application fields with special needs such as medical treatment, hygiene, biological pharmaceutical, microelectronics, automobile manufacturing, experimental scientific research, food processing, schools, etc.

| Model | Indoor type | HMZK060 DHWR |

HMZK070 DHWR |

HMZ K090 DHWR |

HMZK110 DHWR |

HMZK130 DHWR |

HMZK160 DHWR |

HMZK180 DHWR |

HMZK260 DHWR |

HMZK300 DHWR |

HMZK410 DHWR |

HMZK490 DHWR |

|

| Outdoor | Name | HMAO100 | HMAO120 | HMAO170 | HMAO200 | HMAO240 | HMAO300 | HMAO360 | HMAO480 | HMAO600 | HMAO720 | HMA0960 | |

| Quantity | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 3 | 3 | 4 | ||

| Rated cooling capacity |

kW | 28.2 | 34.2 | 51 | 59.2 | 68.8 | 86.5 | 102.3 | 132.4 | 171.1 | 199.5 | 266 | |

| Rated Heat capacity |

kW | 30.4 | 36.6 | 54.4 | 62.2 | 72.6 | 92.6 | 107.4 | 142.8 | 182.4 | 214.1 | 282 | |

| Indoor unit | Airflow rate | m³/h | 6100 | 7100 | 9100 | 11000 | 13000 | 16000 | 18000 | 25400 | 30000 | 41300 | 48600 |

| Size | L (mm) | Depending on the number of functional segments | |||||||||||

| W (mm) | 1260 | 1460 | 1460 | 1660 | 1660 | 1860 | 1960 | 2160 | 2360 | 2460 | 3000 | ||

| H (mm) | 960 | 960 | 1160 | 1260 | 1460 | 1460 | 1560 | 1760 | 2060 | 2360 | 2500 | ||

| Residual pressure |

Pa | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | |

| Power of molor |

kW | 4 | 5.5 | 5.5 | 7.5 | 11 | 11 | 11 | 15 | 18.5 | 22 | 30 | |

| T emperature control range |

_ | 16-30℃ | |||||||||||

| Outdoor unit | Compressor type | Fully enclosed whirlpool compressor | |||||||||||

| Outine dimension |

L (mm) | 1100 | 1100 | 1250 | 1250 | 1250 | 1250(1100) | 1250(1100) | 1250 | 1250(1100) | 1250 | 1250 | |

| W (mm) | 1050 | 1050 | 1200 | 1200 | 1200 | 1200(1050) | 1200(1050) | 1200 | 1200(1050) | 1200 | 1200 | ||

| H (mm) | 1174 | 1174 | 1365 | 1365 | 1365 | 1365(1174) | 1365(1174) | 1365 | 1365(1174) | 1365 | 1365 | ||

| power supply | – | 380V /3N~50Hz | |||||||||||

| Efficiency | kW | 9.3 | 11 | 14.2 | 18.9 | 21.5 | 28.4 | 32.3 | 45.8 | 55.4 | 68.7 | 94.6 | |

| Weight | Kg | 265 | 295 | 350 | 540 | 570 | 605 | 1490 | 1940 | 2260 | 2300 | 3000 | |

| Refrigerant | Madel | – | R22 | ||||||||||

| Charge | Kg | 3.75*2 | 4.5*2 | 6*2 | 7.5*2 | 9*2 | 9*2+3.75 | 9*3 | 9*4 | 9*5 | 9*6 | 9*8 | |

| Connector tube |

Liquid pipe | Pipe diameterΦ(mm) |

12.7 | 12.7 | 15.88 | 15.88 | 15.88 | 15.88 | 15.88 | 15.88 | 15.88 | 15.88 | 15.88 |

| Quantity | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 4 | 5 | 6 | 8 | ||

| Steam pipe | Pipe diameterΦ(mm) |

19.05 | 19.05 | 28.6 | 28.6 | 28.6 | 28.6 | 28.6 | 28.6 | 28.6 | 28.6 | 28.6 | |

| Quantity | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 4 | 5 | 6 | 8 | ||

| Condensate pan pipe diameter |

DN | 25 | 25 | 25 | 25 | 25 | 25 | 32 | 32 | 32 | 32 | 32 | |

Indoor combined air handling unit adopts modular design, each module 100 mm, can flexibly design the height and width according to installation site conditions, flexible installation. AHU can be delivered as a whole, or assembled on site as required.

High quality T6 aluminum alloy extrusion molding, excellent strength, beautiful appearance

Adopt 30-50mm thickened double layer panel.

Panel material can adopts high quality color steel plate, galvanized steel plate,stainless steel plate, or Zn-Mg-Al coated steel plate.

Intermediate rigid polyurethane environmental protection material overall foaming molding, has best performance in heat insulation, sound insulation, fire prevention, strength, service life, cleanliness, etc.

Outdoor chiller unit adopts famous brand fully enclosed scroll compressor, high efficiency, low noise and strong liquid impact resist. Indoor combined air handling unit adopts high quality double air inlet centrifugal fan (AMCA certified fan) or plenum fan (optional) or EC fan (optional). Fan impeller and belt tested by dynamic and static balance before leaving the factory, and equipped with anti-vibration measures, Low vibration, low noise operation, and longer life.

Using SCM or PLC control system, operation panel can choose text manual operate or LCD touch screen, controller built-in fuzzy control or PID control, user-friendly interface, easy operation, high reliability. Main electrical components adopt international famous brands Siemens etc , low failure rate and long life, can provide RS485 communication interface for remote monitoring.

Optimized and improved coil gap and copper tube matching aluminum fin structure,with high heat exchange efficiency and large heat exchange coefficient, ensure excellent heat transfer performance. Specially treated aluminum fins improve fins anti-corrosion performance and heat exchanger durability.

Using pipeline simulation design technology, perfect stress data analysis to prevent leakage. It effectively avoid the resonance cause by pipeline and transportation vibration, reduce pipeline damage, increase pipeline noise absorption ability and reduce operation noise.

Adopt full frame structure. All panels are detachable for easy installation and maintenance. With access door for quick inspection and maintenance of internal components. All maintenance work on the single side, no need to reserve another side maintenance space. All components sharp angle passivation treatment.

Various filter levels are optional. Reasonable filter levels configuration can ensure best effect of each level filter. Optional:Chemical filter,Electronic purification filter.

Advantages

With cold & hot source, integrates air handling & automatic control. Less investment, simple system, high efficiency.

Air cooled design, no need machine room, saves space.

Each system can independent maintenance,other systems can run normally.

Indoor and outdoor unit use copper pipe connection, no need cooling tower, cooling water pump, chiller water pump and connecting pipe. Simple control, low cost.

Plug and play

Installation Case

We receive enquiries in English, Español(Ѕраnіѕh), Русский язык (Ruѕѕіаn), Frаnçаіѕ(French) and ÅL. gadl (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!