Product

More Than 20 Professional Technicians Service for You

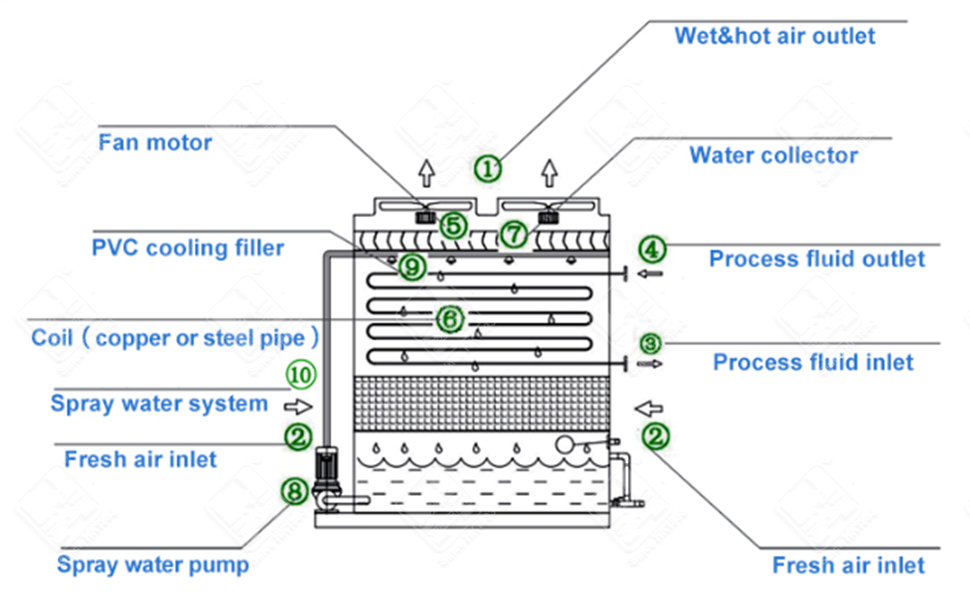

MFB square counterflow closed cooling tower has a compact structure and has more coil heat dissipation area layout compared with composite flow, which is more suitable for low-temperature cooling projects with smaller temperature differences. In addition, it also produces miniature towers, with the smallest cooling capacity of only 5t/h.

Type: MFB Series Counter Flow Type

Flow Rate: 10-500m³/h or customized

Material: Stainless steel/Galvanized steel

Entering Water Temperature Range: 30℃ - 100℃

Coil: Stainless steel/Copper

The inlet grille is made of corrosion-resistant PVC, and its dual-channel design prevents water splashing and reduces the possibility of algae formation inside the unit. The inlet grille around the sink completely encloses the entire sink and prevents direct sunlight from shining into the unit. At the same time, the grille has the advantage of low air resistance.

Difference between square closed cooling tower and traditional open cooling tower

The cooling water of the open cooling tower is in direct contact with the air for heat exchange, so it can not keep the purity of the cooling water system, and the cooling water will inevitably absorb the dust and bacteria in the air. The cooling water of the closed cooling tower flows in the coil, while the spray water and air are outside the coil, so the cooling water and the outside air are not in contact, which can keep the water purity running in the cooling system forever.

The coil made of purple copper or high-quality stainless steel;

Inside with cooling medium, and the outside with spray water cooling.

Low power; low head; large flow rate; low noise; no leakage; long service life.

Special motor for fully closed cooling tower;

Protection class: IP55, insulation class: F;

Adopt Japanese Samsung belt;

Optional: anti-vibration alarm device /global famous brand motor.

Using Magnesium Aluminum galvanized Steel import from POSCO,Korean,higher than the industry standard;

Super anti-corrosion performance can compare to stainless steel;

Processed bending cut place can self-healing and repairing properties;

Available use Stainless steel material according to customer needs;

Ladder,protecting cage and tower top guardrail (optional).

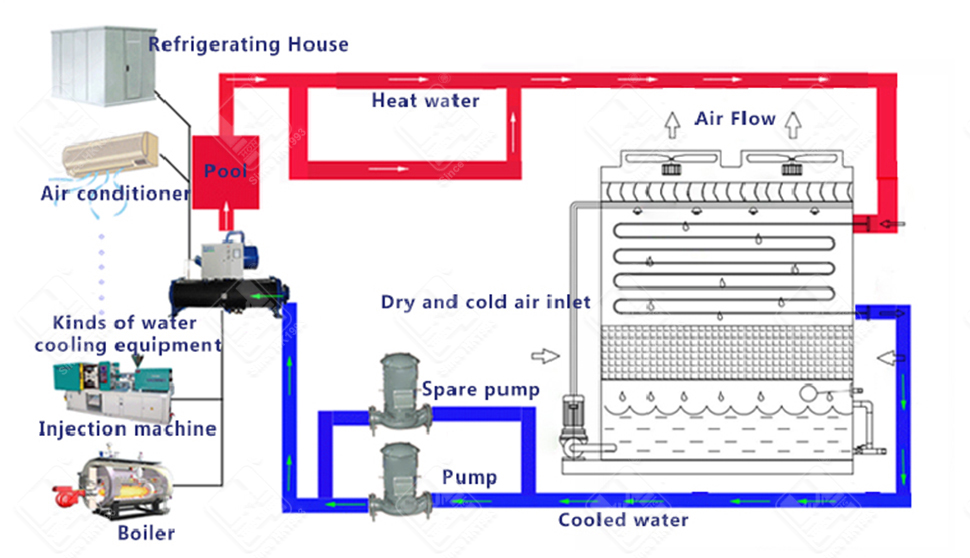

HON MING closed cooling tower is widely used in air conditioning system, frozen series, injection molding, plastic, leather, foam, power generation, food, textile, steam turbine, chemicals, packing industrial, aluminum processing, air compressors, industrial cooling water and other fields.

Cooling water of the cooling tower can provide cooling requirements for the production process and machines in its applying industries:

| Model No | Flow rate (m³/h) |

Fan motor power (KW) |

Pump | Water inlet &outlet diameter(DN) | Weight(kg) | Outline dimension(mm) | ||

| Power(KW) | Flow rate (m³/h) |

Unit weight | Operating weight | LxWxH | ||||

| MFB-5 | 5 | 0.55 | 0.75 | 14 | Dn50 | T:350 | 600 | 1150×900×1920 |

| MFB-8 | 8 | 0.75 | 0.75 | 14 | Dn65 | T:400 | 700 | 1150×900×1920 |

| MFB-10 | 10 | 0.75×2 | 1.1 | 30 | Dn65 | T:520 | 1000 | 2000×1150×2200 |

| MFB-15 | 15 | 0.75×2 | 1.1 | 30 | Dn65 | T:570 | 1100 | 2000×1150×2200 |

| MFB-20 | 20 | 1.1×2 | 1.5 | 40 | Dn80 | T:650 | 1600 | 2500×1150×2200 |

| MFB-25 | 25 | 1.1×2 | 1.5 | 40 | Dn80 | T:750 | 1700 | 2500×1150×2350 |

| MFB-35 | 35 | 1.5×2 | 1.5 | 40 | Dn80 | T:850 | 1800 | 2500×1150×2650 |

| MFB-40 | 40 | 1.5×2 | 1.5 | 60 | Dn100 | T:1050 | 2000 | 2500×1400×2650 |

| 1.5×2 | 1.5 | 60 | Dn100 | G/S:2150 | 3000 | 3000×1400×2650 | ||

| MFB-50 | 50 | 2.2×2 | 1.5 | 60 | Dn100 | T:1250 | 2300 | 2500×1400×2650 |

| 2.2×2 | 1.5 | 60 | Dn100 | G/S:2450 | 3500 | 3000×1400×2650 | ||

| MFB-60 | 60 | 2.6×2 | 1.5 | 60 | Dn100 | T:1350 | 2400 | 2500×1400×2650 |

| 2.6×2 | 1.5 | 60 | Dn100 | G/S:2650 | 3700 | 3000×1400×2650 | ||

| MFB-70 | 70 | 3.5×2 | 2.2 | 65 | Dn100 | T:1650 | 3000 | 3000×1400×2850 |

| 3.5×2 | 2.2 | 65 | Dn100 | G/S:2950 | 4300 | 3518×1400×3310 | ||

| MFB-80 | 80 | 4×2 | 2.2 | 65 | Dn125 | T:1850 | 3300 | 3000×1400×2850 |

| 4×2 | 2.2 | 65 | Dn125 | G/S:3560 | 5000 | 3518×1400×3310 | ||

| MFB-100 | 100 | 4×2 | 3.0 | 110 | Dn125 | T:2050 | 3800 | 3000×2180×2850 |

| 4×2 | 3.0 | 110 | Dn125 | G/S:4150 | 5900 | 3518×2180×3910 | ||

| MFB-125 | 125 | 5.5×2 | 3.0 | 110 | Dn100×2 | T:2450 | 4300 | 3518×2180×3250 |

| 5.5×2 | 4.0 | 140 | Dn100×2 | G/S:5150 | 7000 | 4010×2180×3910 | ||

| MFB-150 | 150 | 7.5×2 | 3.0 | 110 | Dn100×2 | T:3150 | 4300 | 3518×2180×2850 |

| 7.5×2 | 4.0 | 140 | Dn100×2 | G/S:6050 | 8100 | 4010×2180×3910 | ||

| MFB-175 | 175 | 7.5×2 | 5.5 | 170 | Dn100×2 | T:3700 | 7100 | 4010×2980×3910 |

| 7.5×2 | 7.5 | 220 | Dn100×2 | G/S:7120 | 10500 | 5380×2980×3910 | ||

| MFB-200 | 200 | 7.5×2 | 5.5 | 170 | Dn125×2 | T:4180 | 7600 | 4010×2980×3910 |

| 7.5×2 | 7.5 | 210 | Dn125×2 | G/S:8300 | 11700 | 5380×2980×3910 | ||

| MFB-250 | 250 | 11×2 | 5.5 | 170 | Dn125×2 | T:5050 | 8900 | 4510×2980×3910 |

| 11×2 | 7.5 | 220 | Dn125×2 | G/S:10680 | 14600 | 5380×2980×3910 | ||

| MFB-300 | 300 | 7.5×4 | 3×2 | 220 | Dn100×4 | T:6300 | 8600 | 7036×2180×2850 |

| 7.5×4 | 3×2 | 220 | Dn100×4 | G/S:12100 | 16200 | 8020×2180×3910 | ||

| MFB-350 | 350 | 7.5×4 | 5.5×2 | 340 | Dn100×4 | T:7400 | 14200 | 8020×2980×3910 |

| 7.5×4 | 7.5×2 | 440 | Dn100×4 | G/S:14240 | 21000 | 10760×2980×3910 | ||

| MFB-400 | 400 | 7.5×4 | 5.5×2 | 340 | Dn125×4 | T:8360 | 15200 | 8020×2980×3910 |

| 7.5×4 | 7.5×2 | 440 | Dn125×4 | G/S:16600 | 23400 | 10760×2980×3910 | ||

| MFB-500 | 500 | 11×4 | 5.5×2 | 340 | Dn125×4 | T:10100 | 17800 | 8020×2980×3910 |

| 11×4 | 7.5×2 | 440 | Dn125×4 | G/S:21360 | 29200 | 10760×2980×3910 | ||

※Specifications are subject to change without notice.

*More coils with large area cooling area

*Suit lower temperature cooling project

*Saving more space to increase the cooling area

*Reduce floor area with min 5T/h cooling capacity

Small closed cooling tower contact with circulating pump,circulating water tank and control system to from whole equipment. More convenient for user.

More suit to cool the middle-low temperature or small temperature range fluid.

*Made of anti-corrosion PVC material.

*Easy to disassemble

*Made of anti-corrosion PVC materials

*The 2-channel design avoid generate the alga.

*Reducing the maintenance cost

*Less wind resistance and power saving

Advantages

Installation Case

We receive enquiries in English, Español(Ѕраnіѕh), Русский язык (Ruѕѕіаn), Frаnçаіѕ(French) and ÅL. gadl (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!