Product

More Than 20 Professional Technicians Service for You

"HON MING" HM full series of closed circuit cross flow cooling tower has passed by CTI certification. Both of single side, double side air intake, serpentine coil and high efficiency fling combination,there are up to 500 certificated models. The standard water flow max up to 650m3/hr. Standard SS304 coil adopt the most advanced serpentine coil continuous bending technology in China, with max pressure of 2.0 MPa.

Type: HM Series double-side air-intake

Water Flow: 60-650m³/h or customized

Material: SS304/Zn-Mg-Al coated steel

Entering Water Temperature: 30℃ - 100℃

Coil: SS304/Copper

“HON MING” HM full series of closed circuit cross flow cooling tower has passed by CTI certification. Both of single side, double side air intake, serpentine coil and high efficiency fling combination,there are up to 500 certificated models. The standard water flow max up to 650m3/hr. Standard SS304 coil adopt the most advanced serpentine coil continuous bending technology in China, with max pressure of 2.0 MPa. The cross flow design with open structure allows maintenance of flling, sprinkler system, and coil during operation. According to customer water quality and temperature requirements, there are different coil options (red copper, large diameter coil, straight through coil) and optional items.

Difference between square closed cooling tower and traditional open cooling tower

The cooling water of the open cooling tower is in direct contact with the air for heat exchange, so it can not keep the purity of the cooling water system, and the cooling water will inevitably absorb the dust and bacteria in the air. The cooling water of the closed cooling tower flows in the coil, while the spray water and air are outside the coil, so the cooling water and the outside air are not in contact, which can keep the water purity running in the cooling system forever.

Standard SS304.

1 inch serpentine coil with continuous forming.

More diameter, thickness, and material options.

Zinc/Mg plate is higher than the industry standard.

Self-healing properties of bending and scratch.

Optional:SS304.

Optional: ladder cage&safety handrail.

Special cooling tower spray pump(Chuanyuan brand).

Large water flow, small pump head, high efficiency.

Adjustable Angle, stable air flow with high efficiency.

Corrosion resistance, excellent stability, long life service.

Various fan schemes can be selected according to noise requirements.

Three-in-one for water eliminator, louver, and flling.

High quality PVC, B1 level anti-flame material, oxygen index >32%.

Adopt famous brand high quality transmission belt.

Full series CTI certification, 198 models optional.

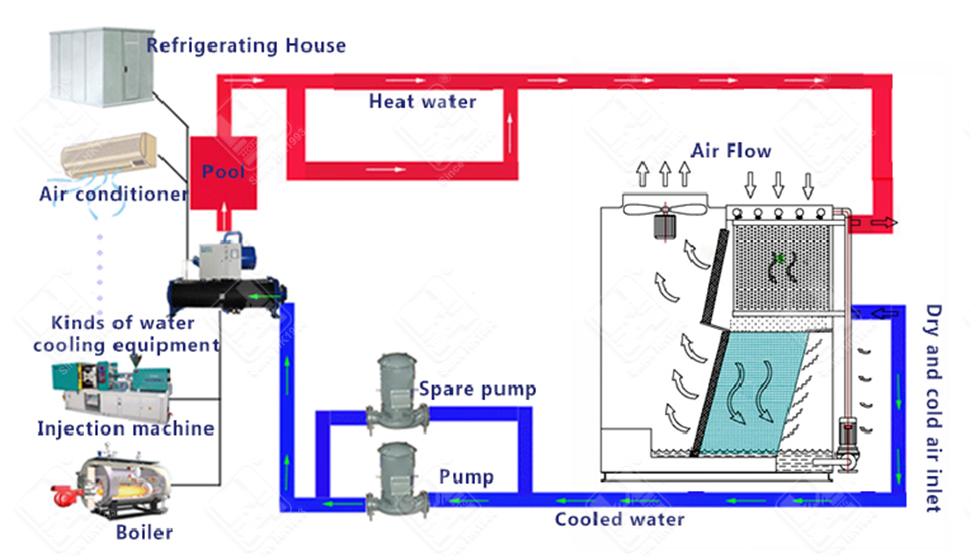

HON MING closed cooling tower is widely used in air conditioning system, frozen series, injection molding, plastic, leather, foam, power generation, food, textile, steam turbine, chemicals, packing industrial, aluminum processing, air compressors, industrial cooling water and other fields.

Cooling water of the cooling tower can provide cooling requirements for the production process and machines in its applying industries:

| Model | Length | Width | Height | Fan | Spray pump | Weight | Pipe inlet dia(DN) | Pipe outlet dia(DN) | ||||||

| L(mm) | W(mm) | H(mm) | H1(mm) | H2(mm) | Power(kw) | QTY(set) | Power(kw) | QTY(set) | Empty(kg) | operatior(kg) | Heaviest(kg) | |||

| HM-3672-202-K | 3660 | 7340 | 5760 | 3170 | 2590 | 7.5 | 1 | 7.5 | 2 | 15000 | 25500 | 5300 | 125*2 | 125*2 |

| HM-3672-202-L | 3660 | 7340 | 5760 | 3170 | 2590 | 11 | 1 | 7.5 | 2 | 15000 | 25500 | 5300 | 125*2 | 125*2 |

| HM-3672-202-N | 3660 | 7340 | 5760 | 3170 | 2590 | 18.5 | 1 | 7.5 | 2 | 15000 | 25500 | 5300 | 150*2 | 150*2 |

| HM-3672-202-Q | 3660 | 7340 | 5760 | 3170 | 2590 | 37 | 1 | 7.5 | 2 | 15000 | 25500 | 5300 | 150*2 | 150*2 |

| HM-3672-242-M | 3660 | 7340 | 5760 | 3170 | 2590 | 15 | 1 | 7.5 | 2 | 15900 | 26800 | 5300 | 150*2 | 150*2 |

| HM-3672-282-O | 3660 | 7340 | 6310 | 3170 | 3140 | 22 | 1 | 7.5 | 2 | 17000 | 28400 | 5300 | 150*2 | 150*2 |

| HM-4278-282-R | 4420 | 8020 | 6310 | 3170 | 3400 | 45 | 1 | 7.5 | 2 | 19200 | 34000 | 5900 | 200*2 | 200*2 |

| HM-4278-322-Q | 4420 | 8020 | 6310 | 3170 | 3400 | 37 | 1 | 7.5 | 2 | 20200 | 35500 | 5900 | 200*2 | 200*2 |

| HM-4278-362-Q | 4420 | 8020 | 6310 | 3170 | 3400 | 37 | 1 | 7.5 | 2 | 21200 | 37000 | 6100 | 200*2 | 200*2 |

| HM-4278-362-R | 4420 | 8020 | 6310 | 3170 | 3400 | 45 | 1 | 7.5 | 2 | 21200 | 37000 | 6100 | 200*2 | 200*2 |

※Specifications are subject to change without notice.

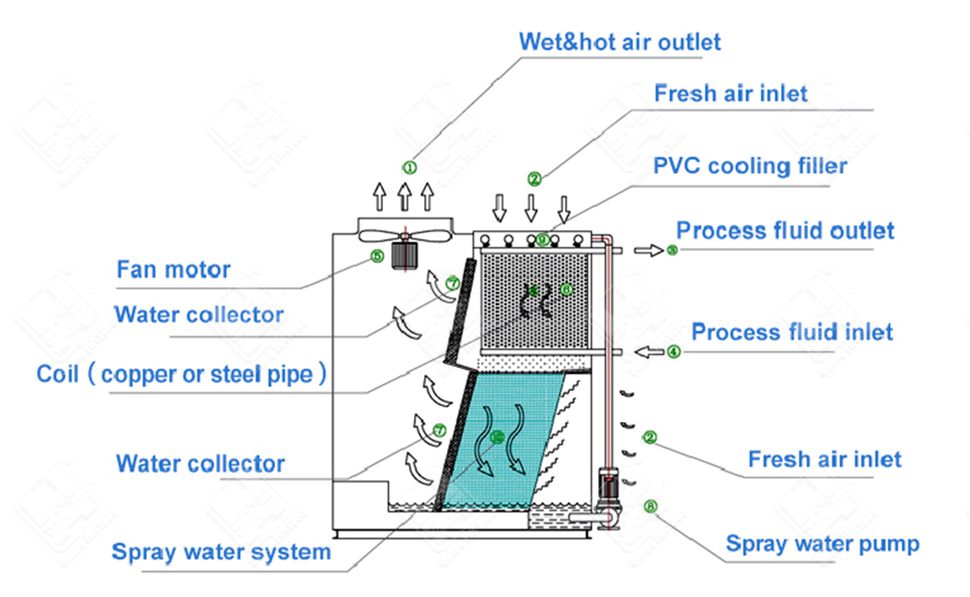

The working fluid (water, oil or other liquid) flows in the coil, and the outer wall of the coil is wrapped by spray water. The heat of the fluid is transferred through the pipe wall to form saturated hot and humid air with water and air. The heat is discharged into the atmosphere by the fan, and the water is blocked back to the water tank for circulating spray, so the consumption is very small. During the circulation, the spray water reduces the water temperature through PV cooling material, and flows in the same direction with the fresh air, the coil mainly relies on sensible heat conduction mode. The important feature of this operation principle is to inhibit the scale formation on the outer wall of the coil as much as possible.

Factory assembly

Modular structure

Single side air inlet and two side air inlet

Low energy consumption, simple and reliable operation, low maintenance cost. The product uses the air-water mixed flow secondary heat exchange coil and PVC filler precooling combination technology to achieve efficient heat exchange. Air and cooling water flow through the surface of the coil in the same direction to ensure that the cooling water can completely cover the surface of the coil, so that the surface of the coil is always completely wet. Compared with the wind water reverse structure, it can effectively avoid the formation of dry spots and structure on the coil surface, and achieve high efficiency heat transfer. The splashing loss is strictly controlled by the design of cross collecting, and the splashing rate is less than 0.001%.

The huge space in the tower provides revolutionary convenience for the routine maintenance of the equipment. The maintenance of the key parts of the coil becomes simple and easy because of the equipment structure. The ball valve and filter can be overhauled without shutdown, and the nozzle and coil can be easily checked when the equipment is running.

This product has unique structure and high thermal performance, so it is a real energy-saving and environment-friendly product with low working medium temperature, operation node, water saving, low noise, no splash and low maintenance cost;

*Using high quality fan and pump

*Without other running spare parts except fan and pump

*Direct type structure have no drive loss

*Low noise and failure rate

*Link with small cooling project through pump and water tank

*Available to form a whole cooling system

*Easy to operate by user

Advantages

Installation Case

We receive enquiries in English, Español(Ѕраnіѕh), Русский язык (Ruѕѕіаn), Frаnçаіѕ(French) and ÅL. gadl (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!