Product

More Than 20 Professional Technicians Service for You

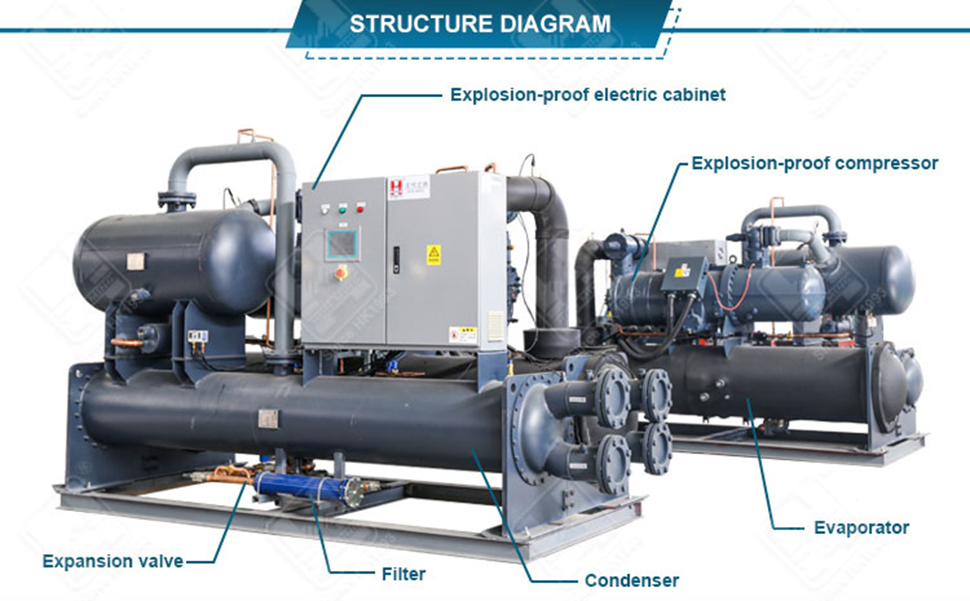

Water cooled screw chiller has advanced chilling technology, with excellent quality, compact structure and beautiful appearance. The full falling film heat exchange technology and the new generation design of two-stage compression, can decreased 40% refrigerant charging volume.

Type: HMWS Series Water Cooled Type

Rated Cooling Capacity: 140kw-1170kw

Working Temperature Range: 3℃~50℃ooling 16℃ -43℃

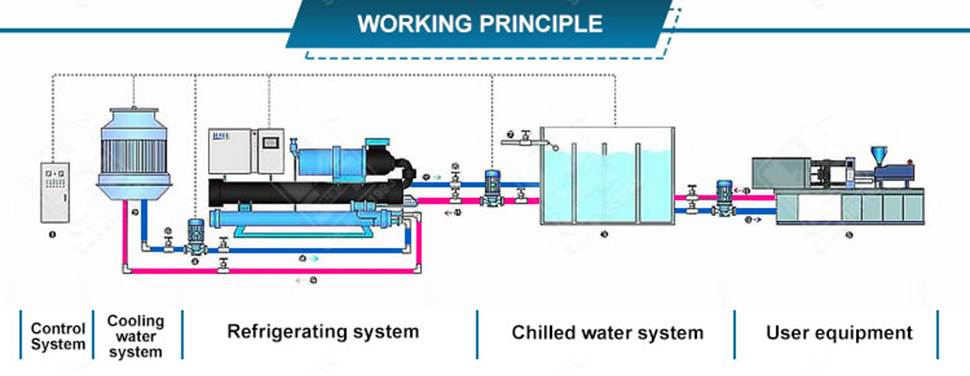

The unit is mainly designed to meet the various requirements of large and medium-sized centralized water-water application system. The design has fully considered the use characteristics and use defects under various climatic conditions to ensure that the air-conditioning system works all-weather.

The water-water heat pump unit can use groundwater, surface water and other water resources as cold and heat sources, achieving cooling in summer and heating in winter at the same time, while taking into account the efficient and clean use of energy.

The whole series of units also provide heat recovery function options, which is convenient for users to take in hot water for domestic use while the unit is cooling, which not only recovers energy but also saves costs.

As the most typical representative product of environmentally friendly and energy-saving air conditioners, the unit can be widely used for centralized refrigeration in hotels, office buildings, schools, shopping malls, restaurants, entertainment centers, health centers, villas, residential quarters, and other commercial and industrial building air conditioners.

It can be used as a living supply source for swimming pools, dairy products processing, beer brewing, cold rolling forging, cold storage and indoor planting, and is especially suitable for communities and service industries.

| Model HMWS | 140GS A1CWLI |

160GS A1CWLI |

170GS A1CWLI |

200GS A1CWLI |

230GS A1CWLI |

280GS A1CWLI |

310GS A1CWLI |

330GS A1CWLI |

390GS A1CWLI |

|

| refrigerant | R22 | |||||||||

| Nominal cooling capacity | *1000kcal/h | 119.2 | 136.2 | 147.4 | 179.1 | 199.3 | 240.2 | 267.4 | 285.0 | 334.7 |

| kw | 138.3 | 158.0 | 171.0 | 207.8 | 231.2 | 278.7 | 310.2 | 330.7 | 388.3 | |

| USRT | 39.3 | 44.9 | 48.6 | 59.1 | 65.7 | 79.2 | 88.2 | 94.0 | 110.4 | |

| Input power | kw | 29.2 | 33.6 | 36.3 | 43.4 | 47.8 | 57.6 | 64.1 | 68.5 | 79.4 |

| Unit running current A | 48.5 | 57.6 | 61.3 | 74 | 80.9 | 103 | 114.7 | 122 | 137 | |

| Power supply | 380V-/3phase/50Hz | |||||||||

| Protection device | Inverse phase protection, lack of phase protection, over current protection, exhaust temperature protection, high and low pressure protection, low temperature protection, water protection | |||||||||

| Refrigeration circuit | 2 | |||||||||

| Energy control % | Infinite capacity adjustment or0,25,37.5,50,62.5,75,87.5,100 | |||||||||

| Control mode | Microcomputer control | |||||||||

| Refrigerant charge volume kg | 24 | 27 | 30 | 35 | 39 | 47 | 52 | 56 | 65 | |

| Condenser | Shell and tube type | |||||||||

| Maximum water side pressure Mpa | 1 | |||||||||

| Heat recovery device inlet and outlet pipe diameter in | 2-1/2N | 2-1/2N | 3N | 3N | 3N | 3N | 4N | 4N | 4N | |

| Cooling water flow m³/h | 28.3 | 32.4 | 35.1 | 42.6 | 47.4 | 57.1 | 63.6 | 67.8 | 79.6 | |

| Water pressure drop of heat recovery device Kpa | 25 | 28 | 29 | 33 | 36 | 42 | 46 | 52 | 61 | |

| Evaporator | Shell and tube type | |||||||||

| Maximum water side pressure Mpa | 1 | |||||||||

| Evaporator inlet and outlet pipe diameter in | 2-1/2N | 2-1/2N | 3N | 3N | 3N | 3N | 4N | 4N | 4N | |

| Cooling water flowm³/h | 23.8 | 27.2 | 29.4 | 35.7 | 39.8 | 47.9 | 53.4 | 56.9 | 66.8 | |

| Evaporator water pressure drop Kpa | 26 | 29 | 31 | 33 | 37 | 40 | 45 | 51 | 60 | |

| Running noise dB(A) | ≤65 | ≤66 | ≤66 | ≤67 | ≤68 | ≤68 | ≤70 | ≤71 | ≤71 | |

| Total Weight kg | 1100 | 1160 | 1220 | 1250 | 1320 | 1490 | 1520 | 1620 | 1710 | |

| Operating weight kg | 1320 | 1380 | 1460 | 1500 | 1600 | 1770 | 1820 | 1930 | 2110 | |

The unit is mainly designed to meet the various requirements of large and medium-sized centralized water-water application system. The design has fully considered the use characteristics and use defects under various climatic conditions to ensure that the air-conditioning system works all-weather. The whole series of units also provide heat recovery function options, which is convenient for users to take in hot water for domestic use while the unit is cooling, which not only recovers energy but also saves costs.

Water-to-Water air-conditioning system is known as the most energy-saving, most environmentally friendly, and most comfortable application system and is widely praised by governments around the world. Especially in air-conditioning application systems, good and stable working conditions can give full play to water-cooling application systems. Compared with air-cooled units, the power consumption can be reduced by more than 30% under the same annual cooling and air-conditioning load conditions. It has the advantages of flexible application, high efficiency, and environmental protection.

The unit adopts a semi-closed twin-screw compressor of an internationally renowned brand, which has the characteristics of low vibration, low noise, high refrigeration efficiency, high efficiency and energy saving, long service life, stable and reliable operation. Choose refrigeration components and logic control components from world-renowned brands, with stable and reliable quality.

It adopts advanced microcomputer control and luxurious Chinese touch screen man-machine interface, and accepts panel input control commands and remote control commands, which can fully meet the customer’s demand for comfort. In order to meet the centralized control of distributed units in super-large commercial projects, the centralized controller is an optional configuration. For occasions that require remote control of the unit, HON MING control system is a good choice as an optional function. The control system of the unit has a standard RS485 communication interface, which is very convenient for networking.

As the most typical representative product of environmentally friendly and energy-saving air conditioners, the unit can be widely used for centralized refrigeration in hotels, office buildings, schools, shopping malls, restaurants, entertainment centers, health centers, villas, residential quarters, and other commercial and industrial building air conditioners. It can be used as a living supply source for swimming pools, dairy products processing, beer brewing, cold rolling forging, cold storage and indoor planting, and is especially suitable for communities and service industries.

In the main equipment of centralized central air-conditioning, the water-cooled screw unit has fewer moving parts, making the unit size smaller, higher reliability of the main parts, longer service life of main moving parts, and easier to maintain the system. The maintenance equipment required for the central system is greatly reduced.

Installation Case

We receive enquiries in English, Español(Ѕраnіѕh), Русский язык (Ruѕѕіаn), Frаnçаіѕ(French) and ÅL. gadl (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!